With fuel costs accounting for nearly 80% of a plant's operating costs, and with shareholders and consumers alike increasingly demanding that utilities prioritize sustainability, improving energy efficiency is the power generation industry's top priority.

Many operators are turning to new turbine and Industry 4.0 energy management technologies to help achieve this ambition. And while these are obviously important solutions, there is actually a far simpler and less capital-intensive means of improving energy efficiency almost overnight—lubrication.

Small change, big payoff.

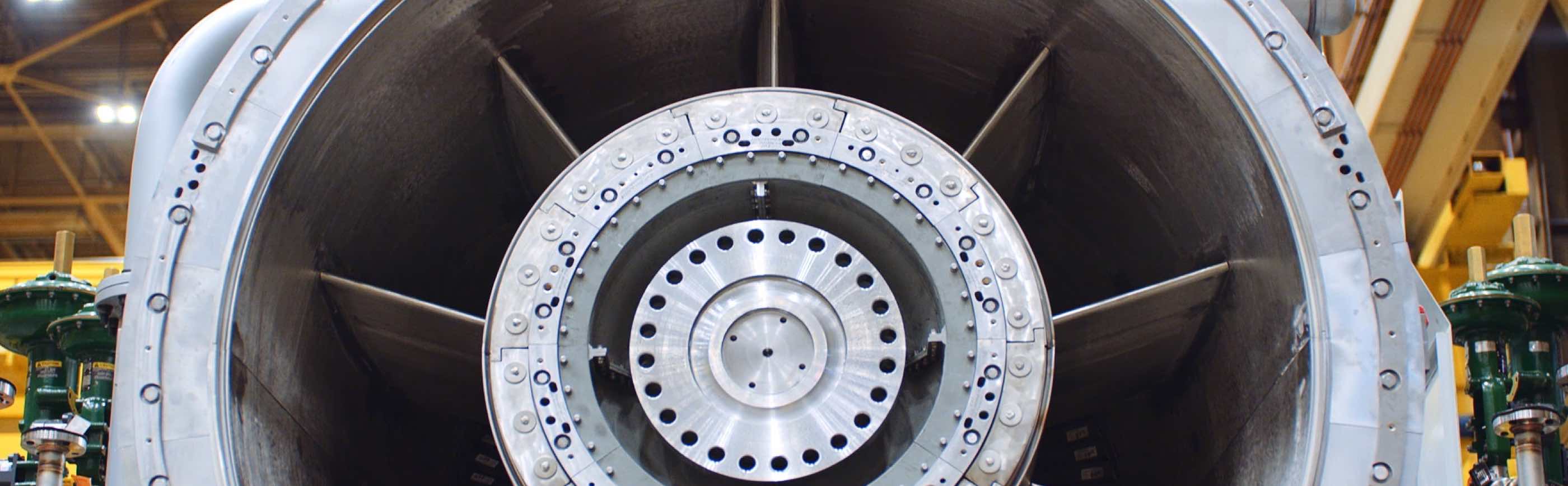

Lubrication is the lifeblood of any industrial machine, and the bigger the machine, the bigger the impact that a best-in-class, customized lubrication strategy can have on performance.

In one case, Duke Energy was experiencing numerous start failures and turbine trips on its GE 7FA turbines. To help solve the issue, the company worked with the Mobil team on a new lubrication strategy using a different oil specifically formulated with properties that could better handle the intense operating conditions of this turbine model, Mobil DTE 732.

After more than three years using an oil better suited to their specific needs, the turbines experienced reduced varnish formation, which helped prevent trips and start failures. This outcome helped Duke Energy improve productivity by preventing unplanned downtime and the associated labor/component replacement costs, generating company-estimated annual savings of $80,000 USD per turbine.

Advanced turbine oil: an energy efficiency solution.

While it’s clear that lubrication has an outsized impact on turbine performance overall, how does it specifically help with energy efficiency?

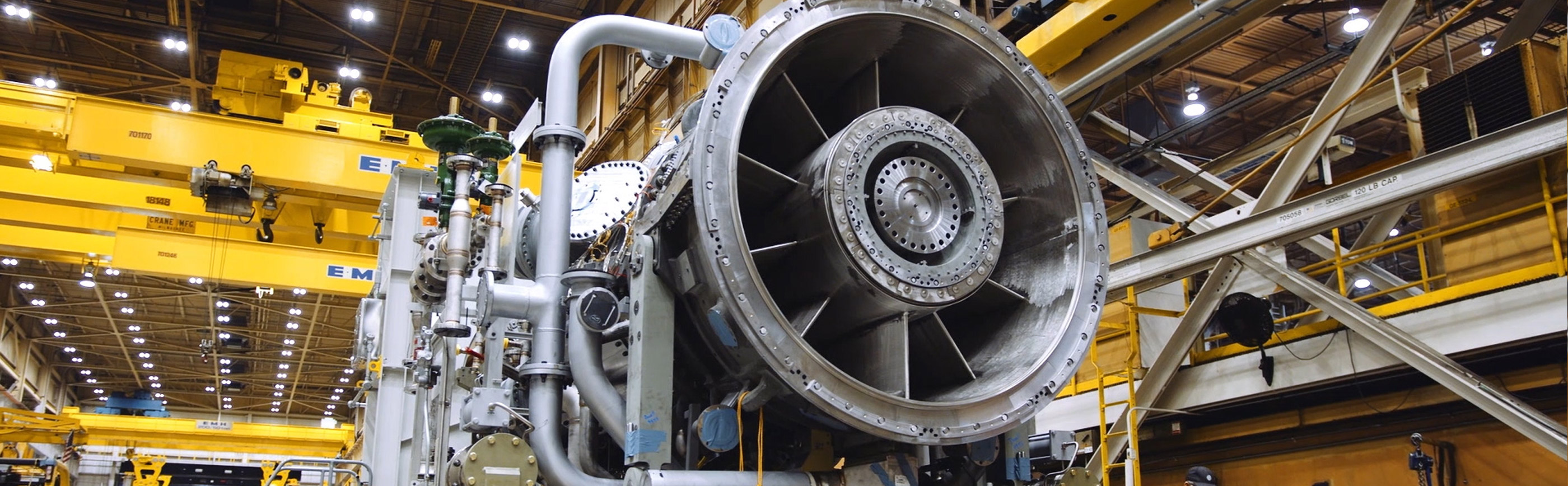

In the case of Duke Energy, simply using an oil better suited to their needs allowed their turbines to operate more efficiently. But there are also lubrication products specifically designed with energy efficiency in mind. With those, the key is thermal stability—which refers to a lubricant’s ability to maintain performance under extreme high temperatures common to gas turbine operation. In the simplest terms, by maintaining its protective characteristics under those higher temperatures, an advanced lubricant can help ensure that the machine keeps “turning” without expending extra energy.

In fact, the thermal stability properties of the new Mobil SHC™ 918 EE gas turbine oil designed in collaboration with GE are good enough to help improve bearing efficiency in GE multi-shaft 7HA and 7FA turbines by up to 15%*.

That's a big boost that can lead to many thousands of dollars in annual savings per turbine.

Take it from ExxonMobil's Beaumont refinery, which is powered by GE Frame 7FA gas turbines:

- The refinery uses an enormous amount of power, and the operation is committed to finding ways to reduce fuel costs and its carbon footprint in the upcoming years.

- To help deliver on these goals, the Mobil team filled one of the refinery's GE Frame 7FA gas turbines with Mobil SHC™ 918 EE, an ISO 32 lubricant designed specifically to enhance bearing efficiency in GE turbines. The refinery is expecting to observe a significant temperature reduction immediately after the initial fill.

Other lubricant characteristics that also influence overall performance—including turbine reliability and extended oil change intervals— include:

- Viscosity index: Having a high viscosity index allows the lubricant to better perform across a wider range of temperatures, which can help with start-up and during the course of regular performance.

- Oxidation stability: Oxidation stability helps protect against oxidation, which is a reaction that occurs when a lubricant is exposed to oxygen. By reducing the impacts of oxidation, the lubricant can perform better over the long term and help protect against rust and corrosion.

Learn more today.

Lubrication may only account for 1% or less of your operating budget, but it can have a far greater impact on your plant's performance.

*Actual results can vary depending upon the type of equipment used and its maintenance, operating conditions and environment, and any prior lubricant used.